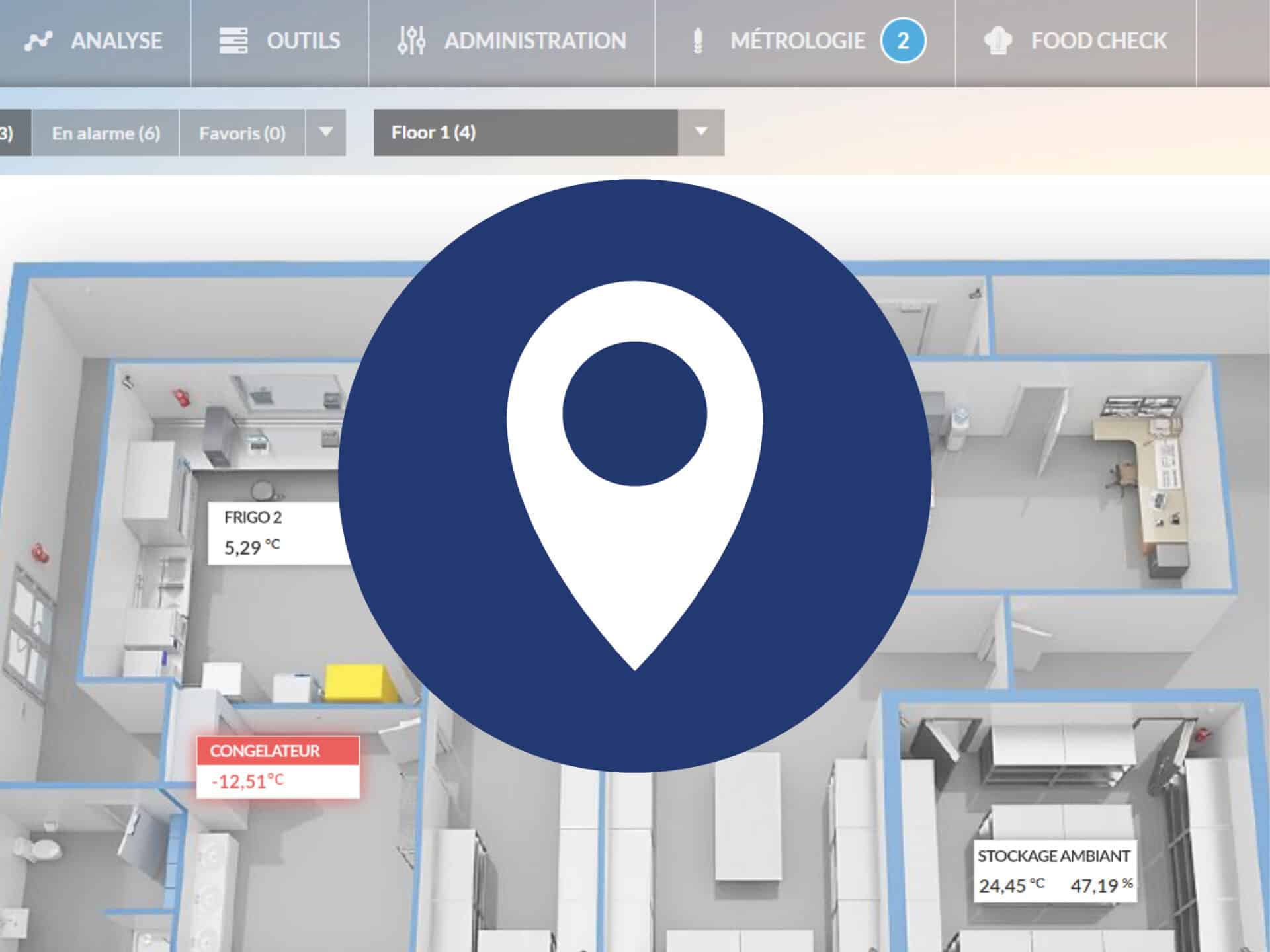

Temperature Control in Catering

Catering requires constant attention to storage conditions to comply with food hygiene regulations. Refrigerated storage, culinary preparations, temperature maintenance, and service are all critical steps that demand continuous monitoring.